|

For maximum Sub Arc productivity, nothing beats Miller's Summit Arc 1000™. Its exclusive variable balance AC squarewave technology provides a guaranteed increase in deposition rates and travel speed — up to 59 percent or more! | ||||

| ||||

|

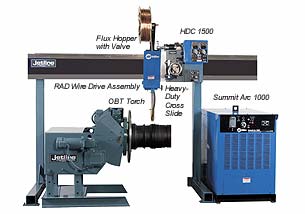

When welding profitably means depositing more pounds of weld metal per hour, no process works harder for you than submerged arc welding (Sub Arc) Sub Arc lets you weld with large diameter wires (1/16" to 7/32") at outputs up to 1250 amps, helping you complete heavy weldments

faster and with outstanding weld quality. Typically an automated process, Sub Arc requires a heavy duty cross slide, welding power source, automatic weld control, flux hopper with valve, wire drive assembly, torch and other components.

Note that many Sub Arc power sources also perform multiple welding processes, typically Flux Cored, spray transfer MIG, Stick and Air Carbon Arc Gouging.

Download Submerged Arc Welding Booklet (pdf)

Sub Arc Productivity Improvements Guaranteed with New

Sub Arc Productivity Improvements Guaranteed with New