|

| |||||

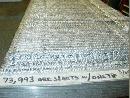

APPLETON, Wis., April 8, 2003 –Miller Electric Mfg. Co. announced that it has developed new arc start technology and has set what it believes to be a world record: 73,993 consecutive pulsed GMAW arc starts with one contact tip. Setting the record consumed more than three miles of wire and six tanks of argon shielding gas during a total accumulated arc-on time of 12 hours, six minutes and 18 seconds.

This technology improves productivity and cost savings, especially in automated GMAW cells where poor arc starts would require manual assistance, causing downtime. Poor starts interrupt production while the operator and /or robot clean spatter, free burnbacks or replace contact tubes or nozzles. Weld quality can also be impacted by incomplete fusion or cosmetic problems caused by poor arc starts.

"We achieved this arc start record under the most difficult starting conditions possible," says Randy Broadwater, product manager, Miller Electric Mfg. Co. "We used 3/64-in. diameter, 4043 aluminum wire. This small diameter melts very easily at low temperatures and is notorious for burning back to the contact tip. Moreover, we directed the wire into the plate perpendicularly for maximum resistance, instead of at the 5 to 15 degree angle normally used to ease starting."

The new Miller arc start technology works by specifying key welding variables–wire type, diameter, wire feed speed, voltage and shielding gas–for the application at hand. The welding power source then chooses from its library of data and selects the optimum arc starting parameters. The first Miller GMAW power sources with this new technology will be available in the summer of 2003.

Getting Started

During an arc start, a GMAW welding system's job is to take the "cold" welding wire and "heat" it (apply current and voltage) to the point where an arc is initiated. Wire feeders that control run-in speed and feature selectable arc start conditions can improve arc starts, as can machines with adjustable slope or inductance control. However, problems still occur.

If the wire strikes the weldment before the arc is established, a "dead short" or short circuit occurs. When a short circuit occurs, the power source clears it by providing sufficient amperage to melt the wire and re-establish the arc. However, if the power source provides too much current at one time, the wire receives more current (heat) than it can carry. At that point, an explosive start will occur, which in turn creates the potential for burnbacks, excess spatter, "cat whiskers" of wire or incomplete fusion.

The new start routines provide the world's most positive arc starts for the following reason: The software tailors the starting parameters and the power source's reaction to starting conditions to the specific application at hand. The power source can now initiate the arc without creating large current overshoots that cause explosive starts.

For more information on Miller's new arc start technology, contact Randy Broadwater at rbroad@MillerWelds.com or 920-954-3814.